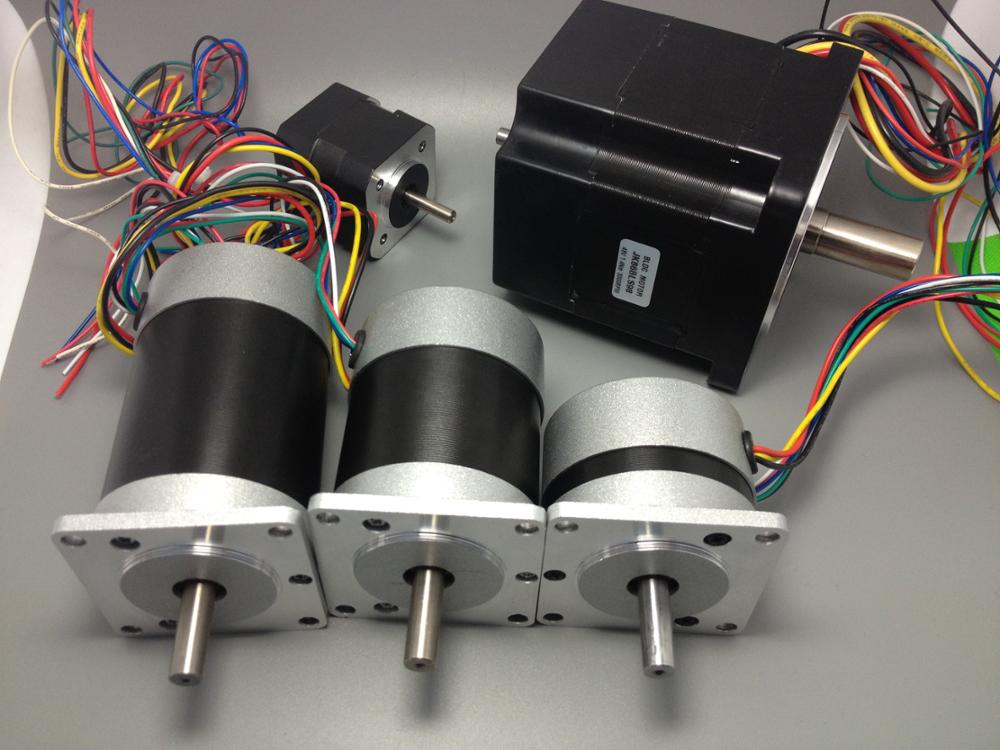

The brushless DC motor is quickly gaining popularity across several industries. BLDC motor design houses don’t use brushes for commutation; they use electricity instead.

From the aerospace industry to home entertainment, brushless DC motor manufacturers tout the following benefits over brush motors in motion-control applications:

- Durability – a brushless DC motor can last much longer.

- Higher efficiency and less wasted heat.

- Lighter in weight.

- Available in compact sizes.

- Simpler to maintain.

- Less noise produced.

- Inexpensive to manufacture.

- More reliable.

- BLDC motor design houses contaminate the components less.

- Good for use in smaller devices.

- No commutators used.

- It’s simpler for the brushless DC motor to quickly change directions.

- The torque-to-size ratio is higher.

- More cost-effective than brushed motors in regards to maintenance, energy and downtime.

- BLDC motor design houses are available in a variety of configurations.